Designer Series / Installation

Quick and easy installation

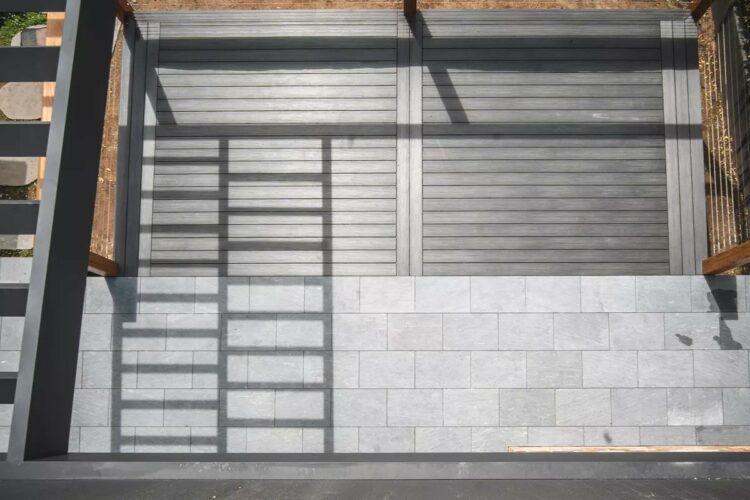

Install Designer Series with Quickfix and achieve a flawless finish with a surface free of fasteners.

Installing with Quickfix is easy for DIYers and at least 30% faster for the trade.

Say goodbye to marking screw positions, pre-drilling and countersinking your boards! The simple clip system automatically gaps the boards saving you time and money with its ease and speed of installation.

Gaps and span

| Residential centre-to-centre joist spacing (max)* | 450mm |

| Residential centre-to-centre joist spacing (max) for stairs and landings* | 400mm |

| Commercial centre-to-centre joist spacing (max)* | 400mm |

| Min. ground clearance (with adequate drainage) | 40mm |

| Min. ground clearance (without adequate drainage) | 90mm |

| Min. side-to-side gap (board spacing) | 3mm or 6mm, auto-spaced by clip |

| Recommended end gap | Refer to installation guide |

Get that professional finish

Cut your boards oversize, install them with Quickfix, now trim all at the same time.

For more of that professional finish check out our Pro-Tips

Need our best cleaning tips for your new Ekodeck Designer Series deck?

Get started with Ekodeck

Experience our entire colour range for yourself. We deliver a sample kit complete with each colour direct to your door.