What is Ekodeck?

So you’ve come to the decision that you’re going to put a deck in your outdoor area – whether it’s replacing an old, worn existing timber deck, or you’re starting from scratch.

Now it’s time to decide on the material you’re going to use for the deck, and you’ve heard the name Ekodeck tossed around as a timber decking alternative but are unsure of what kind of material it is.

So, what is Ekodeck?

At its core, Ekodeck represents a combination of materials engineered to minimise environmental impact while delivering superior performance.

Comprising of a mix of reclaimed timber and recycled plastics, Ekodeck strikes a delicate balance between natural elements and modern technology.

Ekodeck is a wood-plastic composite material, made up predominantly from a mix of high-density polyethylene (plastics) and hardwood timber.

The two main components of Ekodeck are:

Reclaimed Timber:

Ekodeck incorporates reclaimed timber fibers sourced from various post-industrial furniture and flooring businesses.

This timber is often derived from hardwood offcuts, sawdust, and wood scraps – which diverts these timber materials that would otherwise go straight to landfill, and gives them a new purpose.

By repurposing these otherwise discarded wood products, Ekodeck significantly reduces the demand for virgin timber, thereby alleviating deforestation.

Recycled Plastics:

Complementing the timber components, Ekodeck integrates recycled HDPE (High-Density Polyethylene) plastics, usually sourced from items like milk bottles, shampoo containers, and other recyclable plastics from local post-industrial and consumer waste management companies.

This inclusion of recycled plastics not only reroutes plastic waste from oceans and landfills but also minimises the reliance on virgin plastics, curbing the environmental burden associated with their production.

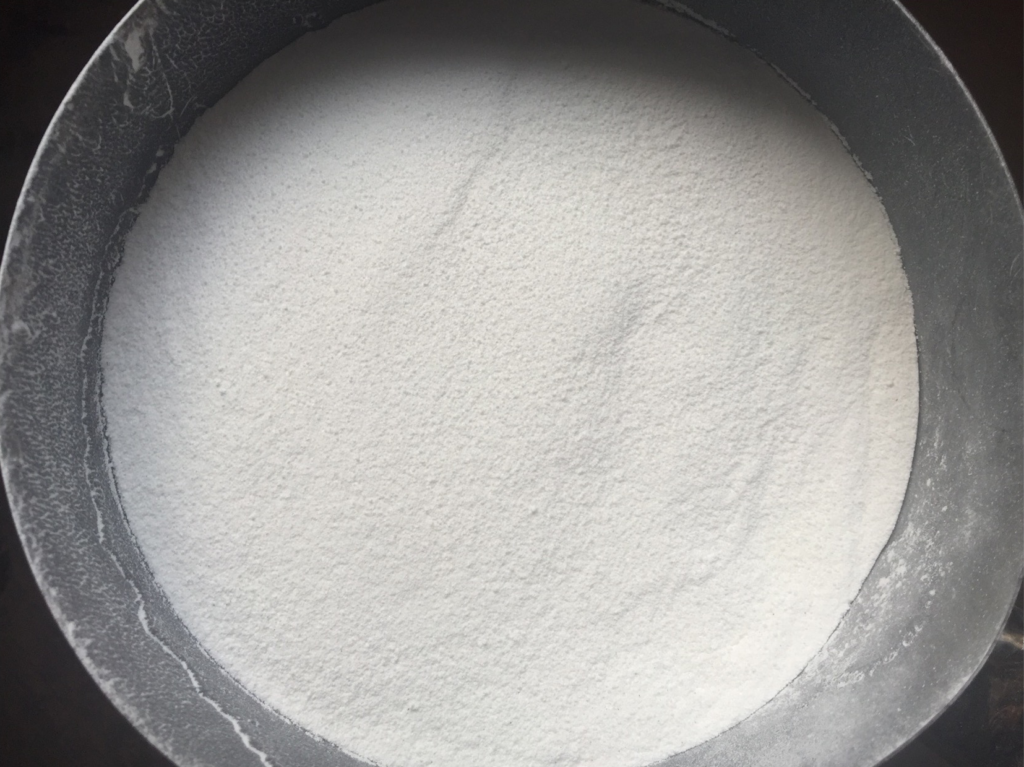

There are also a few additives included in the mix.

Bonding Agents and Additives:

To ensure structural integrity and longevity, Ekodeck incorporates bonding agents and additives. These components play a crucial role in binding the timber and plastic particles together, enhancing the material’s strength and durability.

Additionally, UV stabilisers are added to protect against fading in the harsh Australian sun.

Colour pigments are also added to create our range of different colour choices.

For our Flame Fighter decking, there is also the flame retardant added to the mix, so that the Flame Fighter range is a BAL-29 rated decking board suitable for use in bushfire-prone areas.

The exact ratios of the materials used to make Ekodeck differs slightly depending on which range of our Ekodeck decking you’re looking at.

Ekodeck Classic boards are made from 48% reclaimed timber and 43% recycled HDPE, with the remaining 9% made up of UV stabilisers, colour pigments and other additives.

The Designer Series decking boards consist of 56% reclaimed timber, 25% recycled HDPE, 10% virgin plastics and 9% UV stabilisers, colour pigments and other additives.

Our BAL-29 rated boards, Flame Fighter, consist of the same materials as the Designer Series, with a fire retardant included in the mix that make up the 9% of additives.

All Ekodeck decking boards are fully compliant with the National Construction Code (NCC) for installation in both residential and commercial applications across Australia.

Ekodeck Classic and Ekodeck Designer Series decking boards are Global GreenTagCertTM GreenRateTM Level C certified, using up to 90% reclaimed and recycled inputs, making them the smart timber decking alternative.

You may also like

Get started with Ekodeck

Experience our entire colour range for yourself. We deliver a sample kit complete with each colour direct to your door.